FAQ

What is the CS1/CS2?

- It is a passive video web inspection system used to monitor the quality of print and eliminate any mistakes before it turns into wasted material.

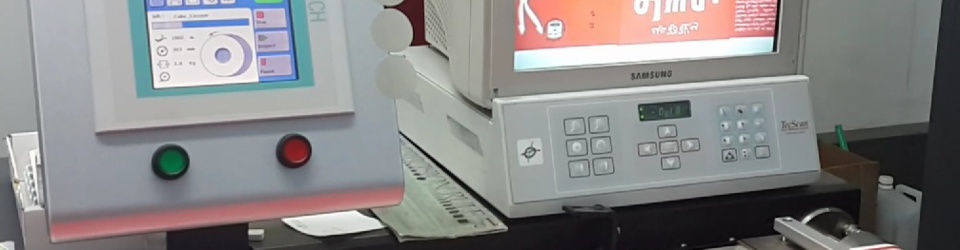

What is the CS3/CS4?

- It is a computer derived video web inspection system with high resolution, user friendly controls and many unique features. These systems assist the operator to achieve a higher standard of quality at higher speed press runs than any other passive video web inspection system, with minimum waste and faster make ready times.

How does the technology work?

- It uses a high quality, super H.A.D technology, Sony FCB camera, to capture images of the print. This image is then relayed on to the monitor for the operator to inspect the quality, colour and any defects that might be present in the print. The system is synchronised to the repeat length by entering the print cylinder gear tooth number.

What types of material/jobs can be inspected?

- The CS1/CS2 systems can inspect the quality of printed labels, packaging, security print and holograms, or any other printed material. They can be used to conduct “on-line” registration. Foil, for metallic ink and foil substrate viewing, can also be inpected. The UV mode can allow the operator to inspect for defects in invisible ink and OBS/OPAS viewing and the back strobe feature allows for front to back register viewing with a single camera system. The CS3/CS4 system can conduct all of the above features with added benefits such as defect detection using a high resolution camera, constant scan mode, image storage for make ready process, user friendly touch screen monitor and multi programmable positional scan.

What benefits does the system provide?

- A video web inspection system can reduce waste to a minimum. It can also reduce the amount of wasted products, increasing productivity and profits. It will reduce the “make ready” process which occurs with every printing job and the operators’ involvement is reduced to increase productivity with employees. Compact camera case allows it to be fit onto any press and the split screen mode allows the operator to compare live images against stored images. Extra options include back strobe for see through viewing, specialist lighting for cold seal, UV, Security Inks and metallic substrate. Also additional options can be provided on request such as a motorised traverse, larger viewing area, additional monitors, remote keypad, second camera and TFT monitor.

What is cold seal?

- Cold seal is an adhesive used in confectionary and food packaging. It has unique properties- it is an adhesive that will only stick to itself and is used to construct hermetically sealed packages and envelopes. The registration of the print on one side, to cold seal on the other, is specified by the end user and must be accurate and reliable. Registration that is outside the specification could cause the seal to be unsafe and introduce sealing problems which means a risk of contamination and cause potential health and safety issues, as well as disrupting production.

How does the Cold Seal Registration Inspection System work?

- This system produces an image of the printed cold seal overlay and in the same view with the image of the register mark on the printed side. This allows the printer to instantly monitor the print to cold seal registration live, in real time at any speed. The system has been very enthusiastically received by both printers and production staff.

What is the Board Watcher?

- The Board Watcher is a machine vision system which uses the latest video technology to inspect and monitor issues associated with corrugated products. It analyses the position and presence of individual colour blocks.

What is the maximum speed of the inspection, and size of the product?

- The maximum 100% inspection speed is 3 boards per second, a total of 180 boards per minute and the length and width of the board size can be unlimited. For more information please refer to our products page.

What is the WEBRANGER?

- The WEBRANGER is an on-line print measuring system which ensures, accurate print length control, eliminates waste during multi set production, improve control over flexible substrates, better control over rewinding, tension and many more.

How does it work?

- The WEBRANGER is a computer based system which displays real time print length measurements of every repeat as double histogram. This allows for real time and long term monitoring which enables analysis of the various parameters that affect print length.

If you have any more questions about your printing requirements...

Simply call us on +44 (0) 1443 821-552 or use our contact form.